For any successful manufacturing firm, it is very important to find a new way to streamline their operations. Starting from the raw materials to WIPs, logistics and of course, the final product, manufacturing is an intricate process with countless moving parts.

Besides the tangible aspects of the manufacturing industry, there are financial and managerial aspects to oversee, not to mention a perpetually changing market demand and aggressive competition.

The manufacturing industry is undergoing a lot of automation, cost pressure is always high and so are the margins. Bringing in efficiency and productivity gain is important to ensure you are competitive as well as profitable. Hence analysing different moving parts spread across functions to make sure they seamlessly work in tandem to bring down the cost, push up the utilization and to increase the margins.

It takes months and extreme due diligence in examining each stage, coming up with innovative ideas and finally implementing them. The recent technological disruptions are not only good for manufacturers’ internal processes but are also a way to remain competitive and achieving organisation goals.

So, how can these organisations improve their underlying manufacturing processes and practices?

Production Analytics For Operational Efficiency:

There are a series of processes going on in parallel and it generates a huge volume of data ranging from machine run-time to no. of units produced. When all this information is decoupled, analysed, and resynched together in a system, the results can be very powerful.

Machinery and systems are constantly operating for long stretches under heavy load and any fault can significantly impact your production. A reactive approach is not sustainable, using predictive analytics systems, factory supervisors can predict such failures in advance and avoid the downtime. A practice that is catching trend is self-correcting machines that warn once such threshold is achieved.

Machine utilisation and effectiveness data can lead to some crucial insights like what has been the run time for each machine, what were the reasons for any deviations from the schedule (human-error, raw-material scarcity, technical issues, etc.). Using analytics systems for Predictive Asset Maintenance is a growing trend across the manufacturing industry, IoT data from sensors can be pulled and analysed to understand the pain areas and help in improving machine efficiency.

The use of analytics is often limited to warehouse optimisation and forward logistics. However, while performing the Reverse Logistics Analytics on numerous occasions organisations have dug up some hidden insights into sunk cost and inefficiencies cropping up from certain activities.

Analysis of returned items provide insights related to which stage of the production process is generating the maximum volume of faulty pieces or end products. It leads to avoiding loss emanating due to customers dissatisfaction as well as the sunk cost associated with manufacturing them. Further, it also adds to optimizing the existing processes, updating the vendor scorecard and ratings.

Free Data Discovery Workshop

Confused about what kind of data analytics tools you need that might help improve your Manufacturing processes, Or any help with the implementation of data analytics tools?

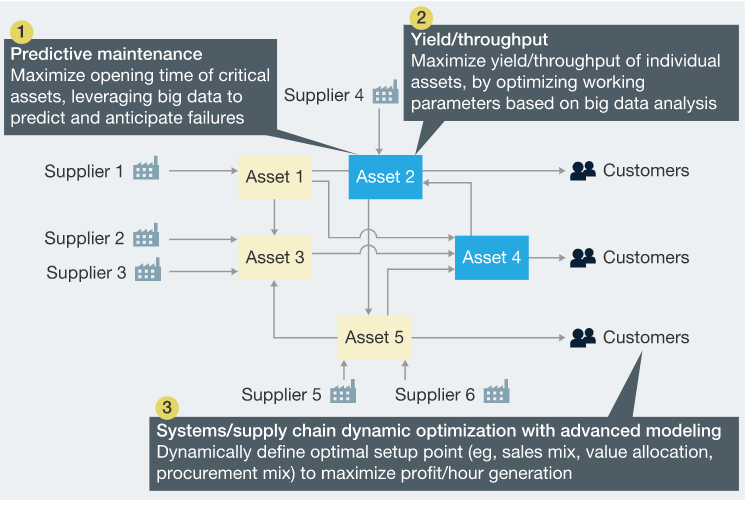

Advanced analytics in manufacturing maximizes operational efficiency through three key applications: Predictive Asset Maintenance, Yield/throughput analysis and Supply chain optimization with advanced modelling.

There are several areas of supply chain management where data analytics can be of significant help.

Now, Suppliers & Manufacturers have a choice to share their production data with their partners and customers to bring in transparency and gain trust. This way the manufacturer can see exactly whether the supplier is delayed with production just in time to avoid any Lead Time. At the same time, the suppliers can pre-empt any such incidence and modify their production output accordingly.

Greater visibility into supplier quality levels and their other performance metrics, manufacturers can have clear visibility on their supplier portfolio and have insightful data in their hands when it comes to supplier contract negotiations. And that ’s how vendor evaluation is one of the most critical functions of any supply chain analytics solution.

Suggested Read: Leveraging Early Warning Systems To Strengthen Supply Chain Risk Management

Having supplier production and quality information available can also provide all the insight needed for better risk management. Supplier dependencies are quantifiable and with timely analysis of this information, the manufacturer can make fact-based decisions for Strategic Risk Management.

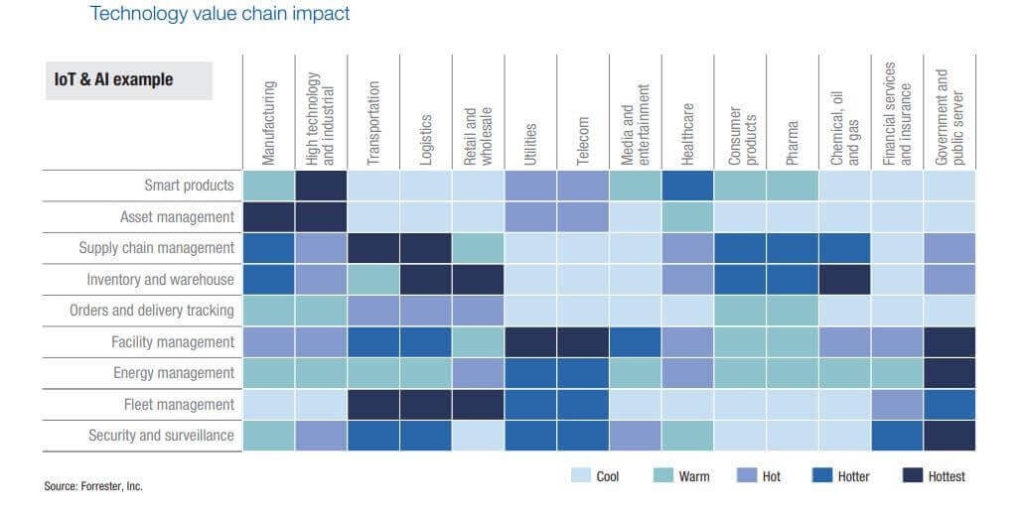

A World Economic Forum (WEF) and A.T. Kearney’s study of the future of production find that manufacturers are evaluating how combining emerging technologies including IoT, AI, and machine learning can improve asset tracking accuracy, supply chain visibility, and inventory optimization.

Source: WEF & A.T. Kearney Report

Manufacturers not only create products for their current customers only, but also for the perceived demand that they expect to emerge soon. Demand forecasting is key because it suggests an optimum capacity for a production chain and that can be the difference between strong sales or a warehouse full of unpurchased inventory.

Traditionally, forecasts are based on previous years’ historic values, and not on more actionable forward-looking data. By combining existing data with predictive analytics to build a more precise projection of what purchasing trends, seasonality, fads and disruptions could be, manufacturers can gain significant competitive advantage. The analytical systems can be trained to also incorporate the market and competition data as well as how well the production lines are operating, leading to smarter risk management and lesser cost emerging due to access inventory storage space.

Capacity Planning: Based on the technology and human capital, the Manufacturer can define the capacity and units of the goods for each production cycle. Using analytics solutions, decision-makers can define an optimal no. of units they should manufacture over a specified period, taking into consideration capacity, sales forecasts, and parallel schedules.

Roping in the daily manufacturing data, the BI Systems can project a clear picture of the actual number of units manufactured over-reporting month in each production unit, making it easy for stakeholders to streamline the workflow and concentrate on the required areas.

Manufacturers must deal with a number of vendors and distribution partners to procure or distribute different parts or finished goods. It is very important to keep a check on the associated costs and the profitability numbers. Having a cost analysis solution that integrates all the information on a single platform and allows you to get actionable insights, can really bring efficiencies across these activities.

Keeping track on the cost per unit of the item is important for a production manager as it impacts the pricing decisions and promotions as well. Calculating it requires data on primary costs (Direct Labour, Direct Material, the cost of raw materials used, overhead costs) and the production units information. Having a BI solution for reporting and visualisation can significantly reduce the risk and suggest timely corrections.

The excessive Overhead costs could be detrimental to manufacturing profitability. To have real control and visibility over these costs, connected data sources and advanced analytics capabilities are needed. Labour cost forms a major chunk of overhead costs. Hence, it is critical to link not only job roles and wages to certain processes but individuals. Employee badges can be tracked with sensors placed on the shop floor. This data can be analysed to assign the exact cost of each task in a process, broken down to an individual’s level. We are observing a growing adoption of these smart IoT devices in the factories.

How Analytics Depot Can Help You In Supply Chain Management Analytics

At Analytics Depot Solutions, we help companies in becoming a connected enterprise where the data sources are connected and everyone in the company has access to the right data, at the right time to achieve operational efficiencies.

If you are looking for a data analytics partner or an offshore engagement, our data science teams can help you set up a robust data management and analytics platform. Why not today and let’s get started?

Want to create winning production strategies?

Learn how powerful visualization and data analytics can help optimize your processes right from raw material sourcing to final product delivery

Subscribe To Our Blogs

Sign up to get the latest news and developments in technology, business analytics, data science and Analytics Depot